Tombola’s DIY spring reverb driver circuit

I’ve been fiddling with spring reverb for a while, probably because of reading Gabriel Roth’s famous “shitty is pretty” article in the late lamented Big Daddy magazine, where he talked about his way of using spring reverb on his throwback funk.

Ages ago I built a little box for this +12v Quasar spring kit, and it sounded ok, if rather hissy. I’ve been using it as my (clanky) main reverb for the last five years or so.

Since then the modular synth thing has gone generally batshit, and Tom of Music Thing recently came up with a spring reverb driver module in 4HP as a smaller alternative to the 8HP Doepfer A-199.

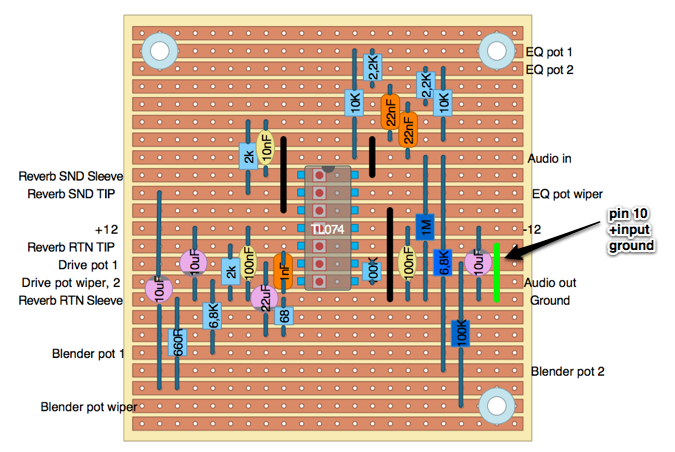

Here’s Muffwiggler user Dego’s stripboard TL074 version, with the additional link to ground on one of the +opamp inputs, which it needs to work. Took me a few months to work that out, aaaaargh:

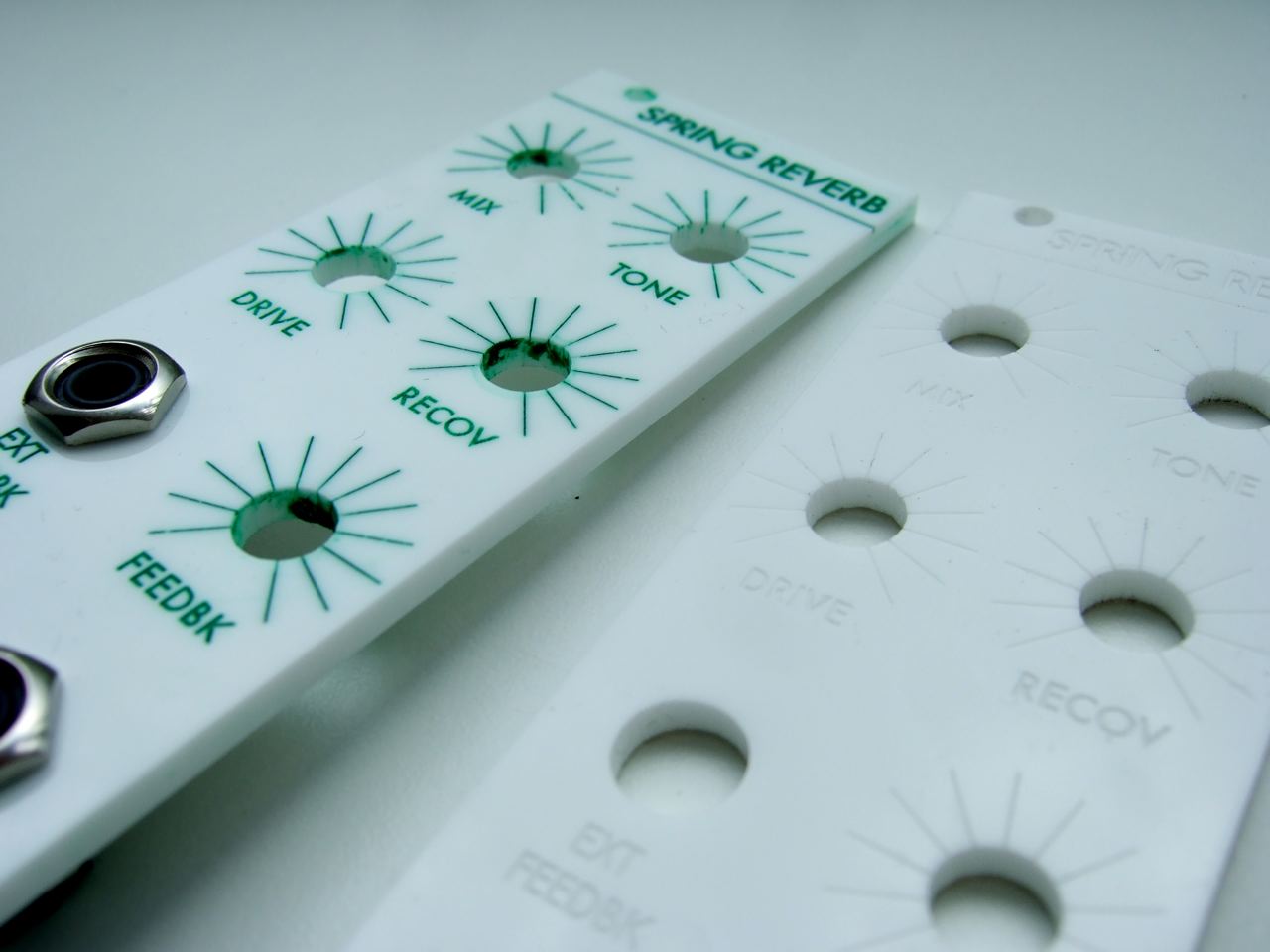

I had some panels for this project in the batch I ordered from Razorlab, this time infilled with emerald green acrylic paint. Makes me want to drink Pimms and eat strawberries and cream. Maximum recommend for Razorlab by the way, although you might have to go via Ponoko to get it done.

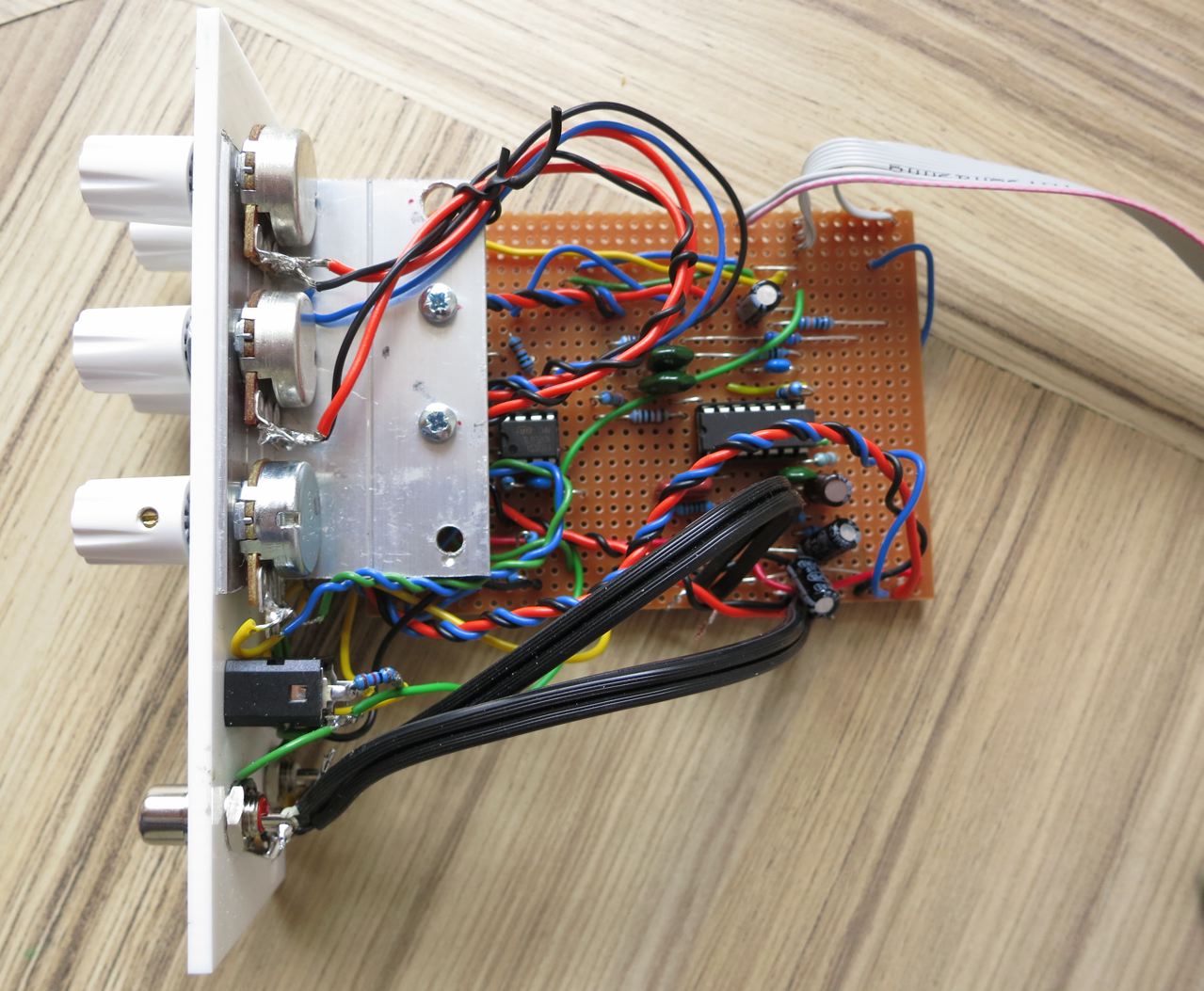

So here’s my version of the module in, erm, 8HP. So I could’ve just bought the Doepfer version then. Anyway. Ta-daaaa.

I added a feedback circuit, with a CGS DC mixer and a switched ext feedback socket – it’s normalled to feed the reverb only signal back into the input, level controlled by the feedback knob. If something is plugged into the ext feedback socket, it mixes that into the input instead. I also added a 1k drive pot instead of the 660R resistor. This helps a lot when switching in different spring tanks via the (handy) phono jacks on the front – most of my motley collection of tanks mostly seem to need a higher drive than the specified 8EB2C1B.

I looked at putting the spring tank connections on a single socket, having missed out on putting an separate output for reverb only, but because the sleeve outputs on the circuit can’t be tied together (they’re not grounded), we’d need a 4-pole socket. Because of the size of the holes in my panel, I tried for one of these.

It turned it out it was nearly impossible to solder wires to the terminals with my clumsily massive iron without melting the plastic dividers. So I gave up and put a stereo jack on the output; one side mix, the other side reverb only.

Round the back, oh dear.

…mmmm. Well it works. My home-made shoddy PCB bracket made out of aluminium L-channel looks a bit better with the blood cleaned off it, at least. I’ve run shielded wires between the board and the sockets for the spring reverb tray in an attempt to try and minimise any hum picked up inside the case.

Because of the additional feedback circuit, added at the eleventh hour, it’s pretty deep and just about fits inside my Doepfer LC9 case. I’d usually favour stripboard but I get the impression that pointboard would produce a more compact layout, probably handy if space is tight. Either way if the sound of springs is your thing I recommend not waiting for someone to knock up a PCB, just have a go.

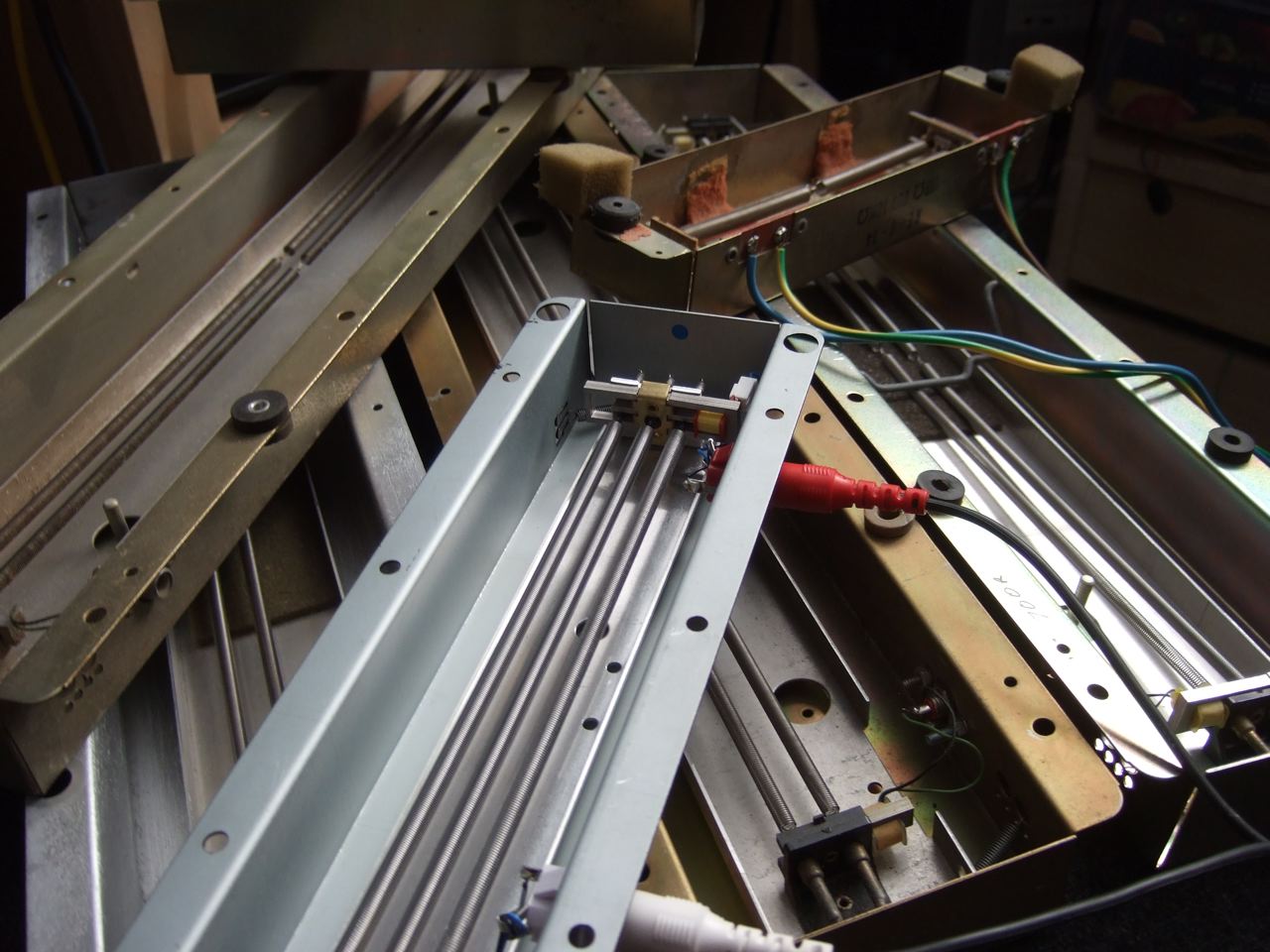

Here’s my pile of springs, mostly ancient trays presumably yanked out of Hammond organs.

And finally some short demos with the specified 3 spring 8EB2C1B tank, just to give an idea of what it sounds like.

This is an early one, fiddling with an MS20, sequenced from the A-155 through the reverb with the driver circuit running at +/-15v. Murky.

Some more beats, the sound source being Marc Bareille’s Polivoks filter clone with the resonance up, being fed through a couple of CGS30 bandpass filters, including some fiddling with feedback, and pushing the drive.

Another loop from the Polivoks/bandpass filter setup.

This is an 8 step sequence from the A155 into an ASys RS95 oscillator. The distortion is the spring being pushed too hard when turning

up the drive. Again at the end I’m playing the feedback, trying to get it ring without whining.

Update – Oct 2013 : Tom Whitwell has designed a PCB for a new version of his spring reverb; all the information over at Music Thing and the inevitable thread over at Muffwiggler.

Oct 2017 : The original schematic seems to have gone walkabout from the thread at Muffwiggler – here it is (updated Feb 2019 with correction to capacitors in tilt EQ subcircuit):

135 comments